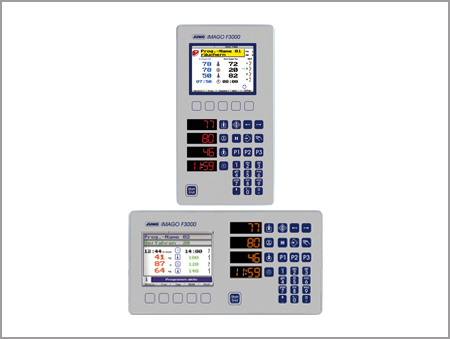

Mini Controller

Mini Controller

1. Process Control for the Meat Processing Industry

Description

The modular process control is suitable for controlling and regulating cooking, smoking, and air conditioning systems as well as all associated devices such as smoke generators, catalysts, etc. It is available in portrait and landscape format.

The device has a 5" color display with 27 colors. The user interface masks can be designed and adapted according to individual requirements. For this purpose it is possible to place texts, process values, background images, and icons wherever the user wishes to do so. A status line shows the last alarm. In addition, LED displays are integrated to allow the most important process variables to be read even from a great distance. Special functions can be assigned to individual keys which can be labeled according to one's choice.

The device saves up to 99 programs including names and 99 sections each.

In 99 process steps all processes required in the system are defined and only need to be invoked when entering the program. A Plug and Play memory is available as an option. This stores all data contained in the device, thereby allowing easy hardware exchange without data loss. The "Teleservice" software allows configuration settings to be made via modem and the telephone network so that an on-site service assignment is not necessary. A communication interface with Modbus or PROFIBUS-DP allows integration into a network.

Features

- 315 × 171 and 171 × 315 mm formats

- 5" color graphic display and LED display with height of 12 mm

- 8 universal measuring inputs

- Two-state/three-state continuous controller, three-step controller, continuous controller

- 4 control channels

- F value, C value, delta T, core temperature

- Inputs/outputs can be expanded in a modular structure

- 99 programs with real-time clock

- Math and logic function

- Recording function

- Modbus interface, PROFIBUS-DP interface

- Self-optimization

- Plug and Play memory

- Configurable via keypad or setup program

Applications

Control and regulation of maturing, cooking, smoking, and air conditioning systems in the meat processing industry.

2. Compact Controllers

Description

The controller series comprises 5 user configurable, universally usable compact controllers in various DIN formats to control temperature, pressure, and other process variables.

The devices are characterized by a simple, clearly structured operation that is supported with texts. Process values and parameters are each shown by an 18-segment display. The types 702112, 702113, and 702114 are additionally equipped with a pixel matrix display for displaying text. In addition, all devices have individual display elements for the switch positions of the digital outputs as well as for manual mode, ramp function, and timer. The devices are operated through a membrane keyboard with 4 keys.

Depending on the hardware design, the devices can be used as a two-state controller, three-state controller, three-step controller, or continuous controller. The basic type includes autotuning, a ramp function, a program controller, manual mode, limit value monitoring functions, binary functions, extensive timer functions, and a service counter. A math and logic function is also available as an option. Furthermore, the user has the option to create his/her own application using structured text (ST code).

The devices can be conveniently configured using a PC with the help of the setup program (incl. program editor and ST editor). No separate voltage supply is required when configuring via the USB interface (USB powered).

Features

- Fixed-setpoint or program controller

- 2 parameter blocks

- Autotuning

- Setpoint changeover (4 setpoint values)

- Ramp function

- Timer function

- 4 limit value monitoring functions

- Service counter

- Individual operating level

- Separate application using structured text (ST code; option)

- Math and logic function (option)

- Fast wiring through PUSH-IN technology

- RS485 interface Modbus RTU slave (option)

- Ethernet interface Modbus TCP (option)

Applications

Control of temperatures, pressures, and other process variables.

3. Compact Controller with Program Function

Description

The JUMO dTRON 3xx controller series consists of 4 user programmable devices in various DIN formats to control temperatures, pressures, and other process variables. The devices are used as temperature controllers TR according to DIN EN 14 597 in heat generating plants for the control of temperatures in fluid and gas mediums. The high-contrast, multicolor LCD display for the actual value, setpoint value, and operator guidance consists of 2 four-digit seven-segment displays, 2 single-digit 16-segment displays, display of active setpoint values, 6 relay status indications, and displays for unit, ramp function, and manual mode. Simple operation with 4 keys. The devices can be used as two-state, three-state, three-step controllers, or continuous controllers. Among other things, the controller software includes 1 program or ramp function, 1 parameter block switch, 2 autotuning procedures, 1 math and logic module, and 4 limit value monitors. The linearizations of the common measuring probes are stored; programming of a customer-specific linearization table is possible. A setup program is available for easy-to-use configuration on a PC. The devices can be integrated in a data network through a RS422/485 or PROFIBUS DP interface. The electrical connection is made at the back with screw terminals. The block diagram displays the possible input and output configurations. The option boards are universally applicable for all devices in the series.

Features

- 48 × 48, 48 × 96, 96 × 48, 96 × 96 mm formats

- Universal measurement input

- 1 digital input

- Two-state/three-state continuous controller, three-step controller, continuous controller

- Inputs and outputs can be expanded in a modular structure (see data sheet)

- Timer and ramp function

- Program with 8 sections

- Math and logic function

- 4 limit value monitoring functions

- Modbus and PROFIBUS DP interface

- Standard: 1× universal measurement input, 2× digital inputs, 2× relays, 2× logic output

- Voltage supply for two-wire transmitter (see data sheet)

- Approval DIN EN 14597

Applications

Control of temperatures, pressures, and other process variables.